Product(s)

penergetic t

Partner

Penergetic Ireland

Customer

Kiernan Pig Farms

Trial with 1792 pigs in Ireland: increased ADG, ADFI and better FCR with penergetic t

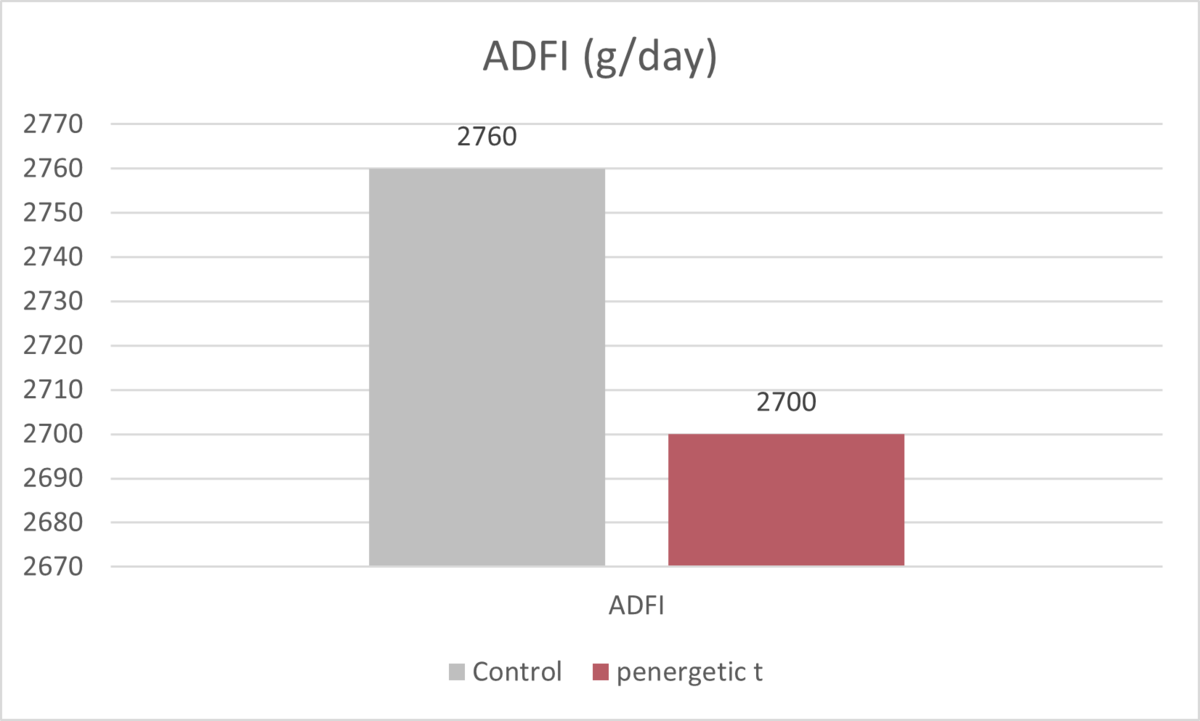

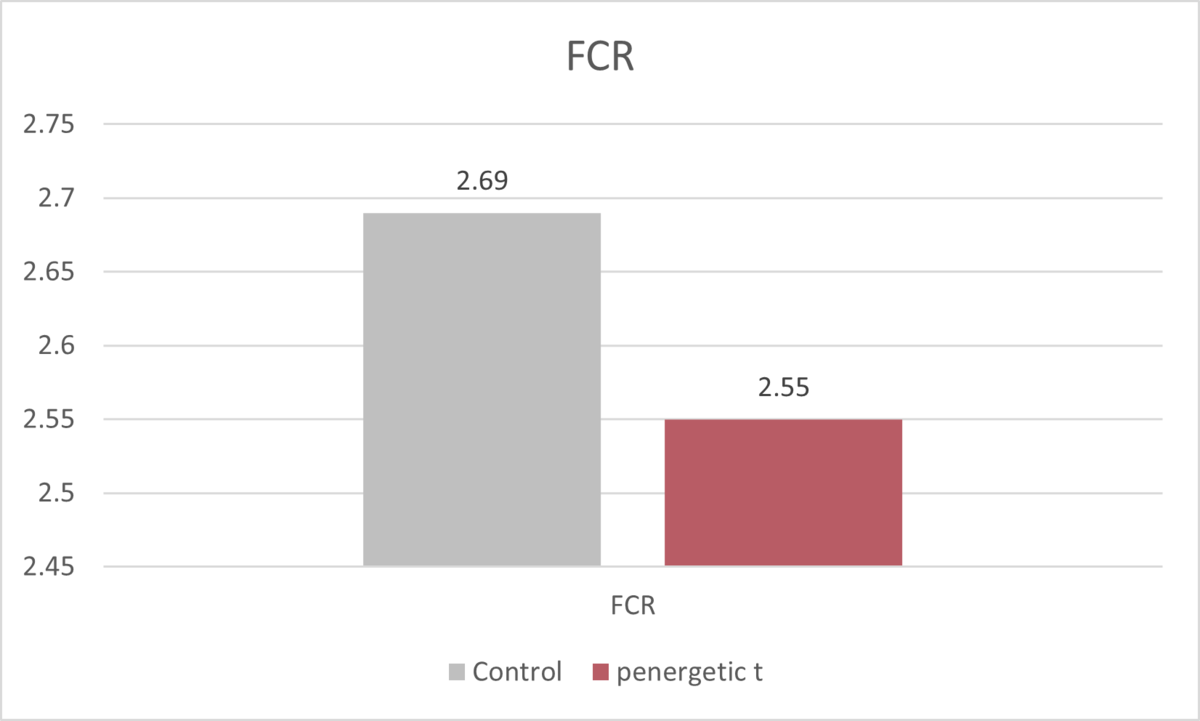

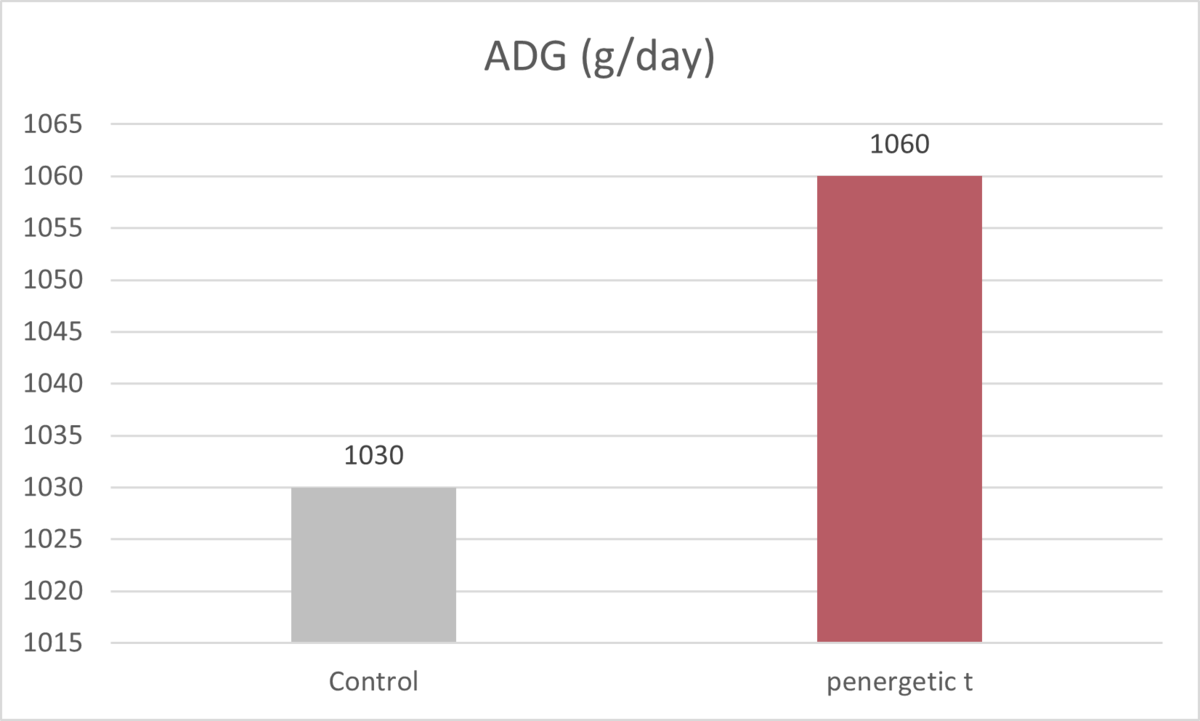

The addition of penergetic t to the standard Kiernan diet resulted in an increase of +2.91% in average daily gain (ADG), reduction of the average daily feed intake (ADFI) of -2.17%, a better feed conversion ratio (FCR) by +5.2% and an increase average sale weight by +1.75% (weight adjusted).

Trial Details

- Number of pigs: 1792 pigs

- Start Date: February 10th, 2021

- Finish Date: May 2021

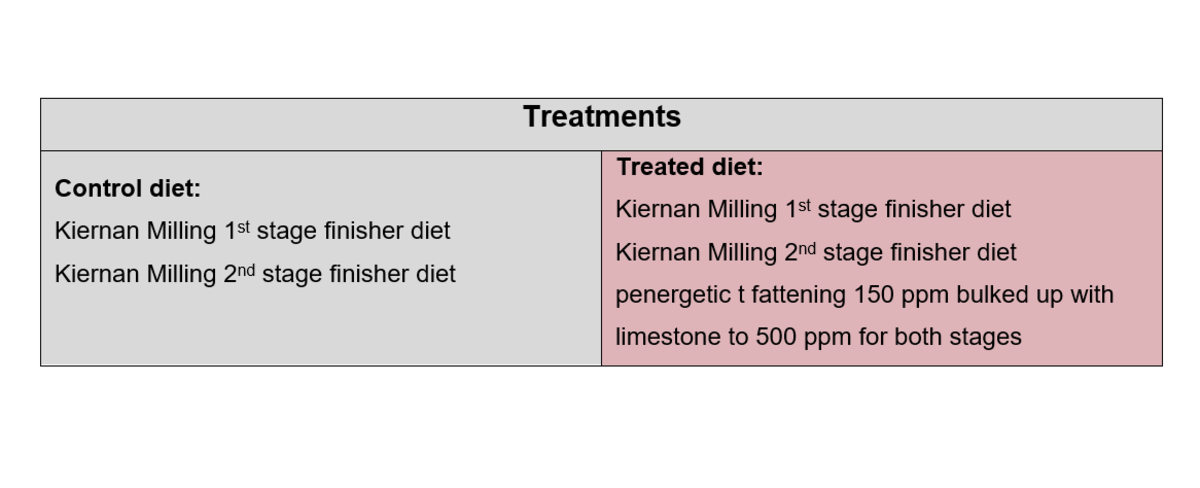

- Treatments:

- Standard Finisher Diet (Control)

- Standard Finisher Diet + penergetic t (Treated)

Site Background

The unit runs an integrated birth to slaughter system and it is of high health status. This finisher unit is dry fed using pellets as produced by Kiernan Milling, with single space feeders (wet and dry). Pens are equipped with 2 feeders per pen (28 pigs). The unit produces approximately 600 pigs per week. The finisher stage operates a two-phase feeding system.

- In week 1, 600 pigs move from 2nd stage weaner houses to the finisher houses. This will partially fill 1 finisher house.

- 600 pigs move from 2nd stage to finisher house a week later. This will fill the remainder of house 1 and begin the filling of house 2.

- 600 pigs move from 2nd stage to finisher house a week later. This will fill the remainder of house 2.

Each house is equipped with a feed bin. This bin is emptied down at the end of the 1st stage finisher (approximately 65 kg liveweight) and pigs move onto the 2nd stage finisher as the feed naturally changes within the bin emptying process. No specific phase feeding transition time is used. Houses are washed between each batch.

Treatments

Treated diets contain 150g of penergetic t per tonne of finished feed for both 1st and 2nd stage finisher diets. As the application rate of penergetic t was too low an inclusion rate for the feed mill, it was bulked up with 350g feed grade limestone for a final inclusion rate of 500 ppm.

Both control and treated diets will have 1.15% lysine in the first stage diet and will drop to 1% lysine in the second stage diet. House 1 was fed the control diet whilst house 2 received the treatment Penergetic.

Results

The addition of penergetic t to the standard Kiernan diet resulted in an increase of +2.91% in average daily gain (ADG), reduction of the average daily feed intake (ADFI) of -2.17%, a better feed conversion ratio (FCR) by +5.2% and an increase average sale weight by +1.75% (weight adjusted).